The usual lifestyle adopted by modern society creates a large amount of plastic waste. This is becoming a growing problem, especially in urban areas as well as oceans, lakes, and rivers. Our environment is flooded with waste plastic.

A Hungarian scientist encountered this problem when, in his multi-year business and scientific career, he became an independent entrepreneur in the field of injection molding of plastic products. From the production process, he had a lot of unusable plastic residues that no one could adequately dispose of, and aware of the long-term and non-degradable nature of waste plastic, as well as the disastrous harm of waste plastic from disposal in landfills, he came up with the idea: INVERTED PLASTIC PRODUCTION PROCEDURE, KNOWN BY THE NAME OF POLYMERIZATION , INTO SOMETHING HE CALLED COLD LOW-PRESSURE DEPOLYMERIZATION. Cold and low-pressure, because the entire depolymerization process takes place at low pressures and low temperatures. Low pressures and low temperature of the depolymerization process is the “main secret” of the process compared to many other processes that try to solve the problem of waste plastic. The result of that idea is the PWED device.

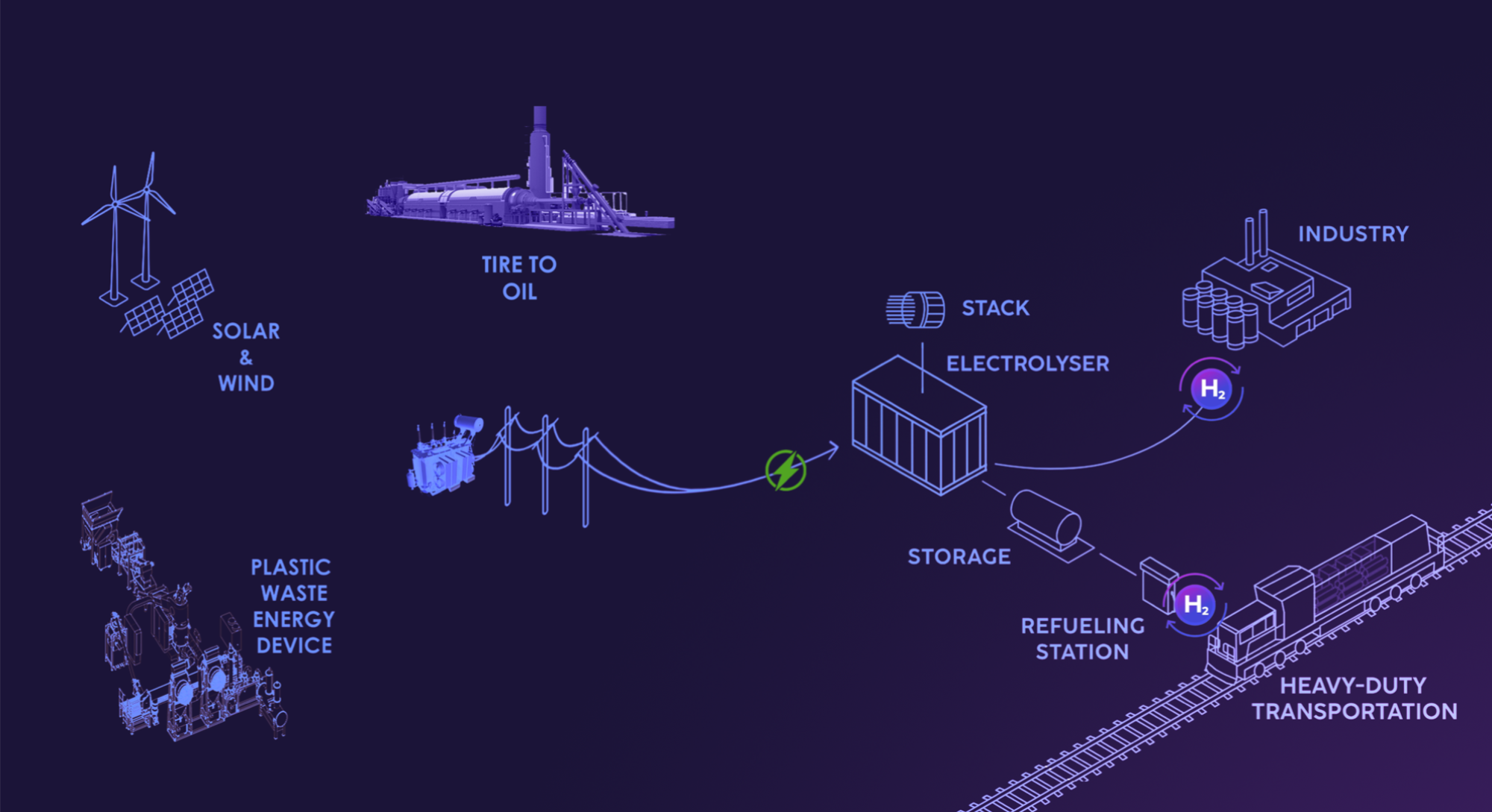

The current PWED is the fourth, improved generation of the device. From the three fractions of diesel and gas, which are the result of the fully closed, cold and low-temperature depolymerization process, electrical and thermal energy is produced in the turbine/generator. You may be wondering why we are going to produce electricity? The answer lies in the fact that the “quality” of the produced fractions of diesel and gas varies according to the type of waste plastic. The turbine/generator used with the PWED is specially designed to withstand variations in the “quality” of diesel and gas and to simultaneously use both fuels to produce electricity. Thermal energy is generated from cooling the turbine/generator.

You may also be wondering, “Why didn’t the Hungarian inventor go to the production of hydrogen?”, because universal decarbonization and transition to hydrogen is in trend? Again the answer is simple. Hydrogen is not a panacea that is a cure for all energy, environmental and economic problems.

Hydrogen is basically just an excellent and environmentally friendly energy carrier. There are two problems with hydrogen, its ecologically and economically acceptable production and its ecologically and economically acceptable distribution. For ecological hydrogen production, there is currently no better way than water electrolysis. Water electrolysis requires cheap energy that is renewable and environmentally friendly, and this is where PWED with its electricity production comes into play, because, unlike wind farms and photovoltaic panels, it can continuously provide stable high-voltage electricity 24 hours a day, on incomparably smaller required areas for installation, and we also get rid of waste plastic fittings.

Thermal energy from PWED can be used for food production in aquaponics food production. Food produced in aquaponics (fish, crustaceans, vegetables and berries) can, again due to the cheap electricity from PWED, be preserved by the best method for long-term preservation, 25+ years, freeze drying. This conservation method leaves all the nutritional ingredients in the canned products, does not destroy the structure and taste of the canned products, drastically reduces the weight of the canned products, and the products, while packed in their original packaging, can be stored at room temperature. When such preserved products are needed for consumption, they are rehydrated with a little water and are ready for the usual preparation.

There are more solutions for the distribution of the produced molecular hydrogen, which is a very small molecule that tends to escape from the tanks:

- solution for storage in special tanks under high pressure and in cryogenic form,

- solution for storage in ammonia which is easy to transport but is very dangerous for the environment,

- solution for storage in LHOC – “hydrogen oil”, known under the name benziltoluen,

- solution for storage in special ccomposite tanks under very high pressure, and

- solution for storeage in REDOX battery storage systems.