Links to chapters

The increasing demand for plastic due to its wide and easy application ultimately results in the accumulation of significant plastic waste. This waste is worrying due to limited efforts, inadequacies, and environmental difficulties of conventional techniques for remediation of waste plas-tics.

The increased production of raw materials for polymer synthesis has a double impact on our ecosystem:

- Causes rapid depletion of non-renewable oil sources and

- It creates waste.

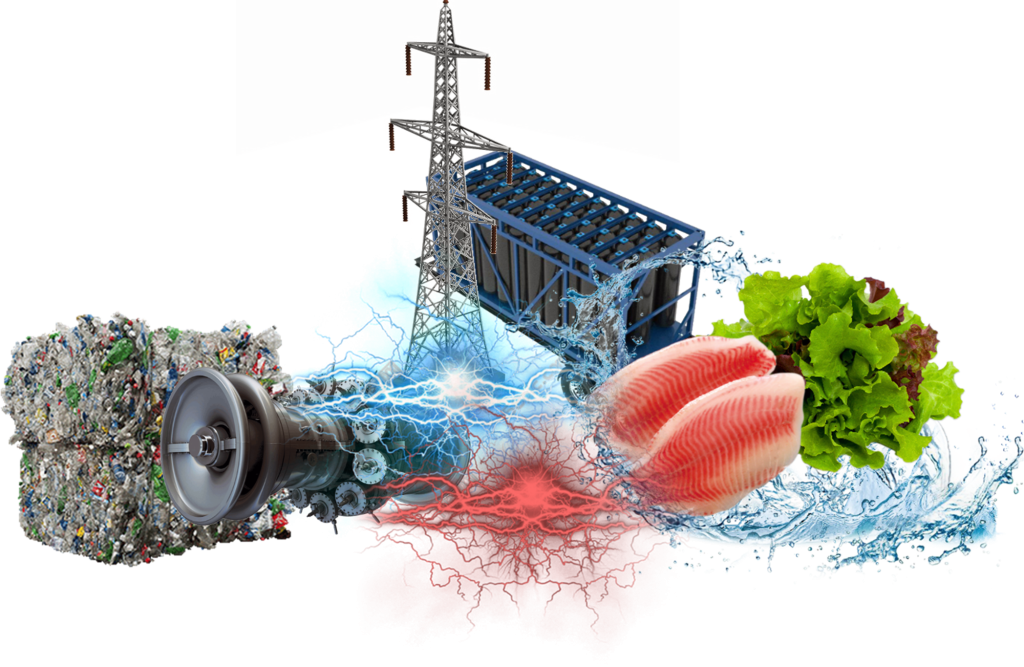

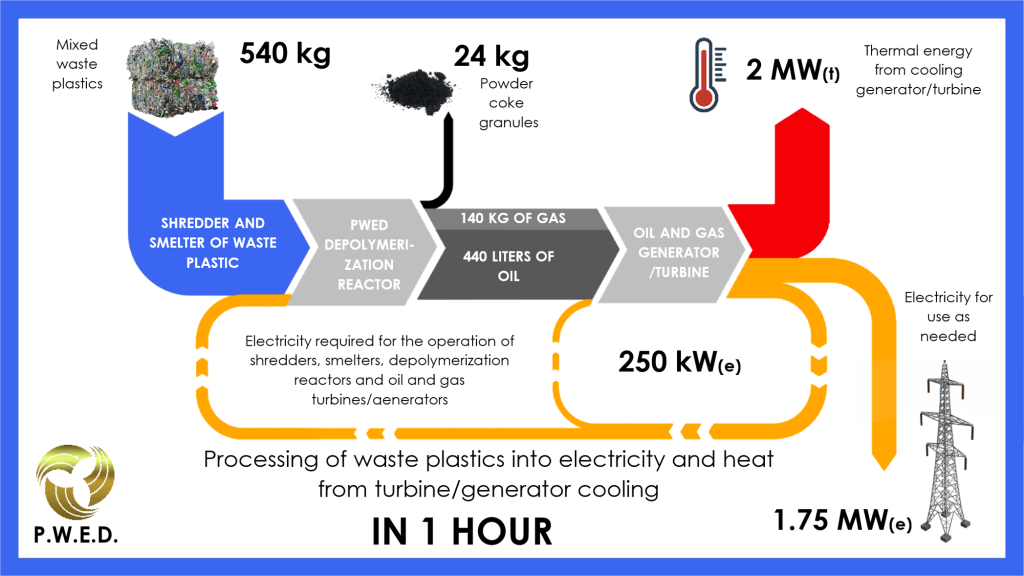

To address this situation, the researchers adopted various advanced recycling processes. We at Eco Spark Global promote the process developed around the depolymerization reactor by P.W.E.D d.o.o. and which has been promoted for several years by Addryn d.o.o. The device we promote is called PWED-2. Plastic Waste Energy Device (PWED) converts in one hour 540 kg of unclassified plastic into 440 liters of oil, 140 kg of gas and 24 kg of fine coke granules. In doing so, no greenhouse gas emissions are generated, microplastics are not created and no ash is created. Oil and gas are used in two-fuel aggregates to produce electricity.

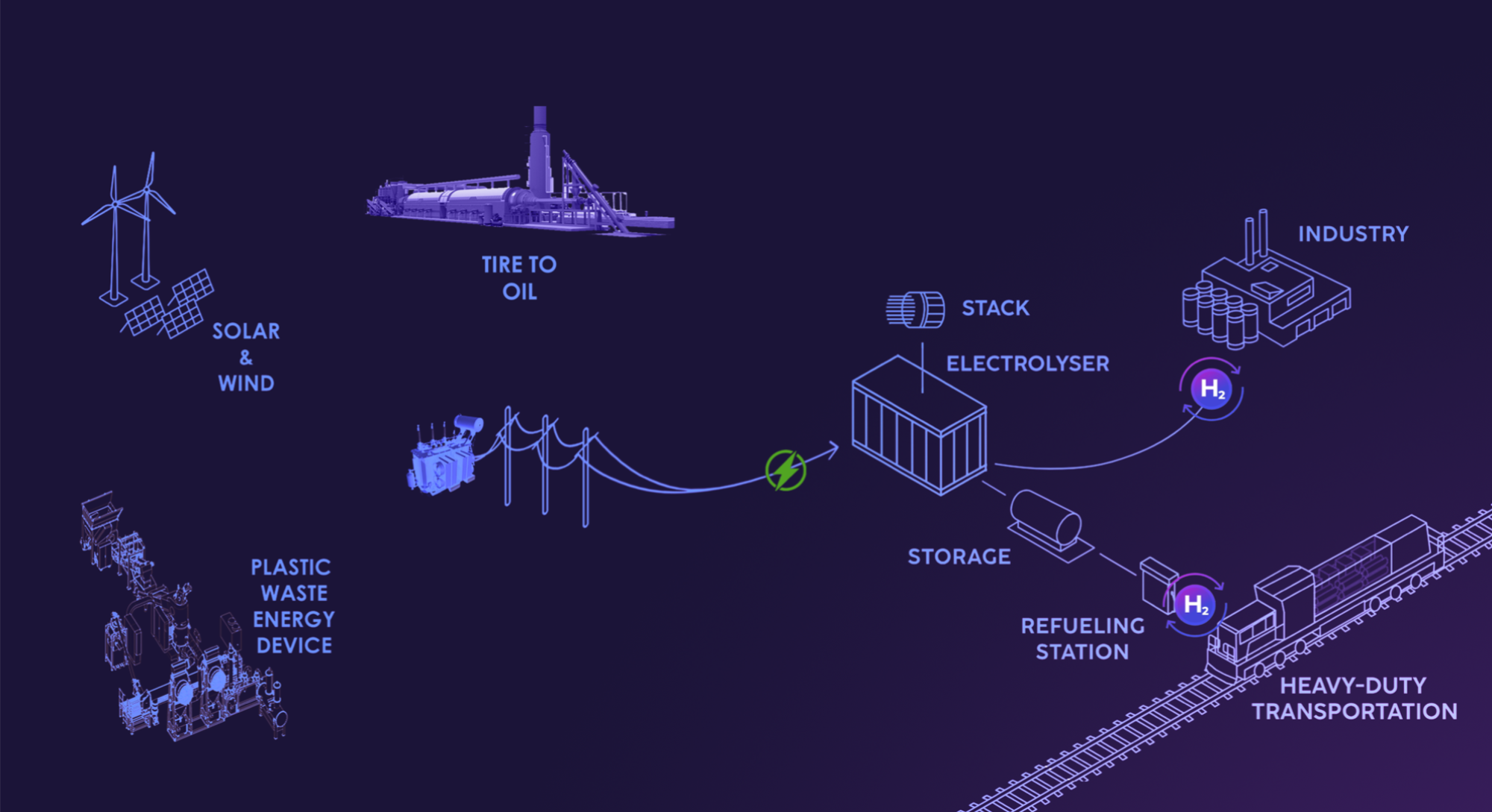

From produced electricity in a two-fuel aggregates, PWED uses 250 kW(e) per hour for its needs, and 1.75 MW(e) is used for various needs. The measures of use of produced electricity from waste plastics are: commissioning into the public electricity grid, use for powering electric vehicles and ferries, production of hydrogen by electrolysis of water, storage in a large electricity warehouse, trading with electricity, … Etc.

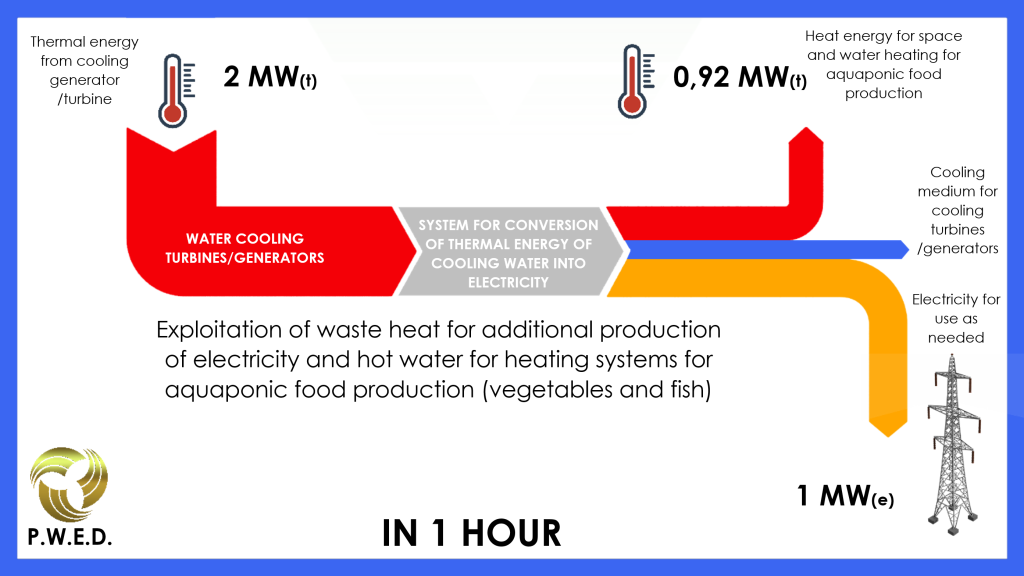

Such a practice serves the purpose of a circular economy. And waste heat, from the cooling system of aggregates, after additional electricity production (with additional equipment that is not an integral part of PWED), is used in aquaponic systems to produce organic food (fish and vegetables).

If you engage in aquaponic food production then, given that you have large amounts of cheap electricity, you can use the freeze-drying process also known as lyophilization for long-term conservation of the produced food. This canning process allows you to use food even after 25+ years, and that such canned food has preserved all nutritional properties as long as it is stored in the original packaging and at room temperature. Yes, freeze-dried food packaged correctly can be stored at room temperature. Preparing such canned food is simple: after rehydrating the food with a little water, the food is ready for all the usual meal preparations.

After intensive promotion of PWED technology, in the last two years, a large number of interested individuals and countries for PWED technology have come forward, and we have decided to launch the company P.W.E.D. d.o.o. in Zagreb, Croatia and produce of PWED-2 line in factory WE-KR in Ivanec, Croatia.

In the picture below, in addition to the red color that indicates the countries from which they are founded or in which the production of the PWED-2 line is, are marked, in different colors, countries that are interested in the right to produce PWED-2 lines for their needs and sell PWED-2 lines in their country. With these countries, a Contract on the distribution and produce of PWED-2 lines worth more than EUR 200 million has been signed or is underway. Most countries are also interested in establishing aquaponic food production along the PWED-2 lines.